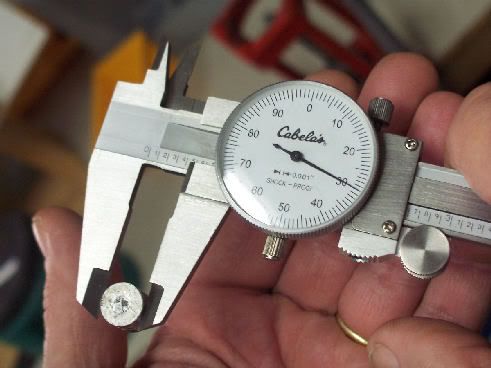

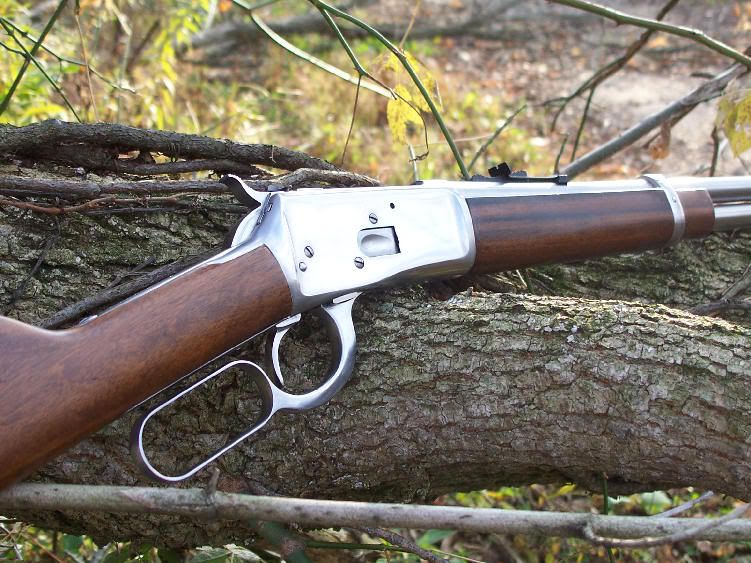

I had a chance to go spend some time with dad today and cast some bullets.We are casting for the 357 Mag and the 44 Mag with the Lee six cavity moulds, the 357 mould is the 158 gr RN and the 44 is the 200 gr RN. This is my third go at it and its getting better as the first two times I was getting the feel of the melting pot and moulds and the entire process.Last time I casted some I was getting little pits and blemishes in the bullets. I had casted around 800 but only 300 was usable. After some investigating and asking questions on the

Leverguns Forum and over at the

Cast Boolit Forum I discovered that my mix was dirty. It was not as clean as I had thought, so I cleaned the Lee 20 melting pot and had a better feel for fluxing the metal as well. Another thing we discovered was we were using 10% tin in the mix WAY TO MUCH!, so we dropped that down to 2% and the results between that and cleaning the melting pot seemed to do the trick.Also it seems like the Lee moulds like to be run hot with much better results as well. I am slowly getting the hang of it, this last pict of the semi circle of bullets is what they are turning out like now....One thing I would like to add is while over at the

cast boolits forum I ran across a fella by the name of goatlips who has an excellent site

Goatlips Blackpowder Tips with tips on smelting, speed casting, and pan lubing all with excellent picts of the process. Check it out, as I have added it to the links section... To Be Continued.